Product Center

5000 Hydrogen peroxide steam sterilizer

The whole sterilization process is divided into four stages

Preparation stage: the temperature of the steam generator is raised to a stable condition

Steam generation: hydrogen peroxide vapor quickly enters the sterilization space (by flash evaporation)

Sterilization stage: the saturated concentration of hydrogen peroxide vapor is kept in the sterilization space

Ventilation stage: hydrogen peroxide vapor is decomposed into water and oxygen on the catalyst

The sterilization process

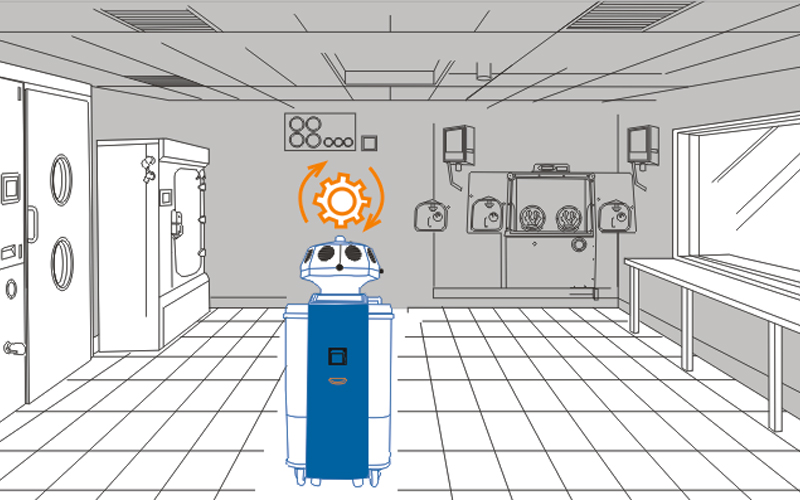

Step 1: Prepare

WDS-5000 sterilization equipment is started, the system is self-tested, to prepare for the work of the flash evaporator.

No pretreatment or dehumidification is required for the sterilized area.

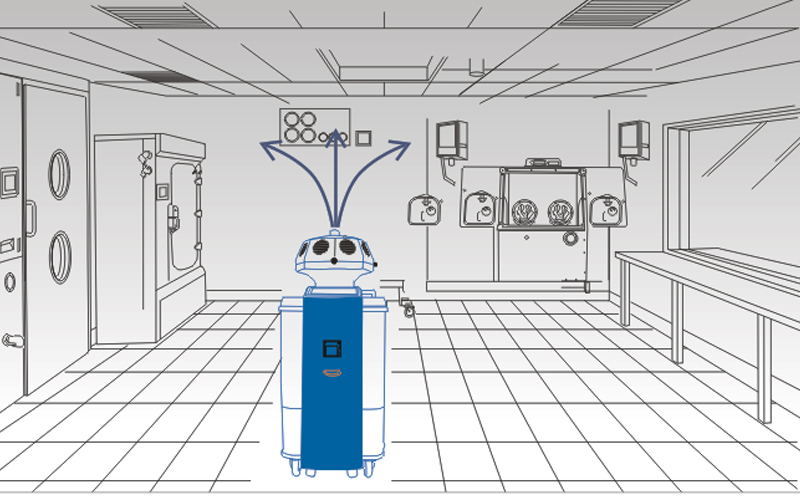

Step 2: Air intake stage

The WDS-5000 flash vapour enters the enclosed space and fills the interior, then diffuses hydrogen peroxide vapour onto every exposed surface, including the complex shapes and crevices around it.

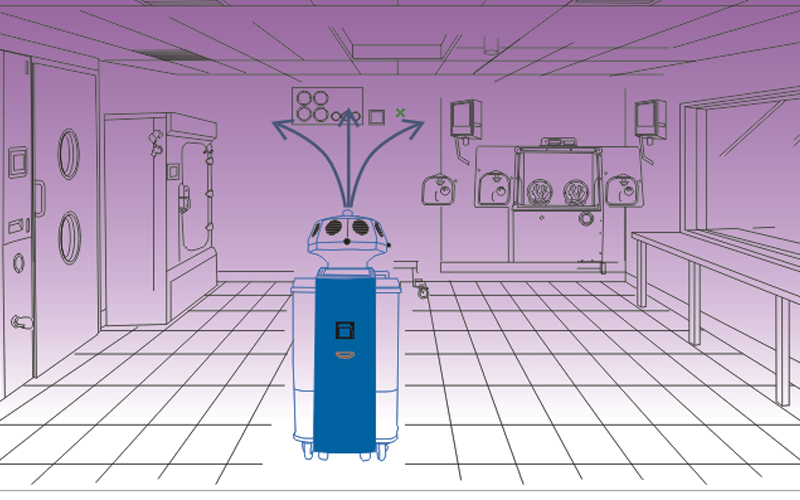

Step 3: Maintenance phase

As the hydrogen peroxide vapor saturates, the enclosed space will no longer be filled with gas, and the vapor will settle on each exposed surface and kill the pathogen.

Step 4: Ventilation stage

All hydrogen peroxide vapors can be safely removed from the space using the WDS-5000 Sterilization Equipment's high-performance catalytic degradation unit. When using the ventilation unit of the equipment, hydrogen peroxide vapor can be degraded into water vapor and oxygen.

| Equipment model | WDS-5000 |

| Structural materials | Aluminum, stainless steel, ABS plastic |

| Operating temperature Storage temperature |

15 ℃ to 30 ℃ 0 ℃ to 35 ℃ |

| Relative humidity of operation Stored relative humidity |

25-75%RH 95%RH (Max, no condensation) |

| The power supply | AC 220V 50/60Hz 16A |

| power | 3200W |

| Work location | upright |

| Dimensions with console (WXDXH) Without console size (WXDXH) |

550 x640x1390 mm 550 x550x1390 mm |

| Weight with console Without the weight of the console |

100 kg 95 kg |

| Maximum hydrogen peroxide solution loading | 5.0 litres |

| Steam gas flow rate Diffusion flow |

60 cubic meters per hour 950 cubic meters per hour |

| Steam temperature | 50-70 ℃ |

| Hydrogen peroxide liquid injection rate | 0-30 g/min |

| The noise | 80 dBA (degradation stage) |

| Hydrogen peroxide | 30-35% W/W Analytical Pure Grade (stored at 2-8 ° C) |

Contact information

Explanation of Enquiry

Contact us

Phone: 0572-2617830

Mobile: 13923700787

Email: ericmj@wds-hz.com (General Manager)

wdszc@wds-hz.com (Sales Manager)

joy@wds-hz.com (General Manager's Office)

Address: 2nd Floor, Building 5, Xiangyi Industrial Technology Park, 1555 Gangnan Road, Huzhou Development Zone

Sterilization equipment

Sterilization equipment

Smart products

Smart products